Concrete nails are typically designed for use in hard materials such as concrete, masonry, or other dense surfaces. The withdrawal resistance of concrete nails in different materials can vary based on factors such as the type of material, the nail design, and the installation method.

Here’s a general overview of how concrete nails for framing perform in terms of withdrawal resistance in different materials:

- Concrete and Masonry:

- Concrete nails are specifically engineered for use in concrete and masonry surfaces. Their design often includes features such as fluted shafts or grooves, which provide enhanced grip and resistance against withdrawal forces in hard materials. The withdrawal resistance in concrete and masonry is typically higher compared to softer materials.

- Wood:

- While concrete nails are primarily intended for use in hard materials, they can be driven into wood to some extent. However, the withdrawal resistance in wood may not be as high as in concrete or masonry. For wood applications, traditional wood nails or screws are often more suitable.

- Steel and Metal Surfaces:

- Concrete nails may also be used in steel or metal surfaces, but their withdrawal resistance can vary depending on the thickness and hardness of the metal. In some cases, specialized fasteners designed for metal applications may be preferred.

- Plastic and Composite Materials:

- Concrete nails are generally not recommended for use in softer materials like plastic or composite materials. Withdrawal resistance in these materials may be limited, and alternative fasteners designed for softer substrates are typically more appropriate.

- Brick and Stone:

- Similar to concrete and masonry, concrete nails are suitable for use in brick and stone surfaces. The withdrawal resistance in these materials depends on their density and hardness.

It’s important to note that the effectiveness of concrete nails in different materials is influenced by factors beyond withdrawal resistance, such as shear strength, bending resistance, and overall structural stability. Additionally, the correct installation method is crucial for maximizing withdrawal resistance. Properly aligning, pre-drilling (if necessary), and driving the concrete nails with the right tools contribute to their performance.

If high withdrawal resistance is a critical factor for a specific application, alternative fastening methods such as anchor bolts, screws, or specialized connectors may be considered. concrete nails for framing Additionally, consulting the manufacturer’s guidelines and recommendations for the specific type of concrete nail and the intended material is essential to ensure optimal performance and safety.

What factors influence the shear strength of structures fastened with concrete nails for framing?

The shear strength of structures fastened with concrete nails for framing is influenced by several factors related to the properties of the nails, the material of the substrate, and the installation process. Understanding these factors is crucial for ensuring the integrity and stability of the fastened structures.

Here are key factors that influence the shear strength:

- Nail Diameter and Length:

- The diameter and length of the concrete nails play a significant role in determining shear strength. Larger diameter and longer nails generally provide greater shear resistance, as they have more surface area and embedment depth in the substrate.

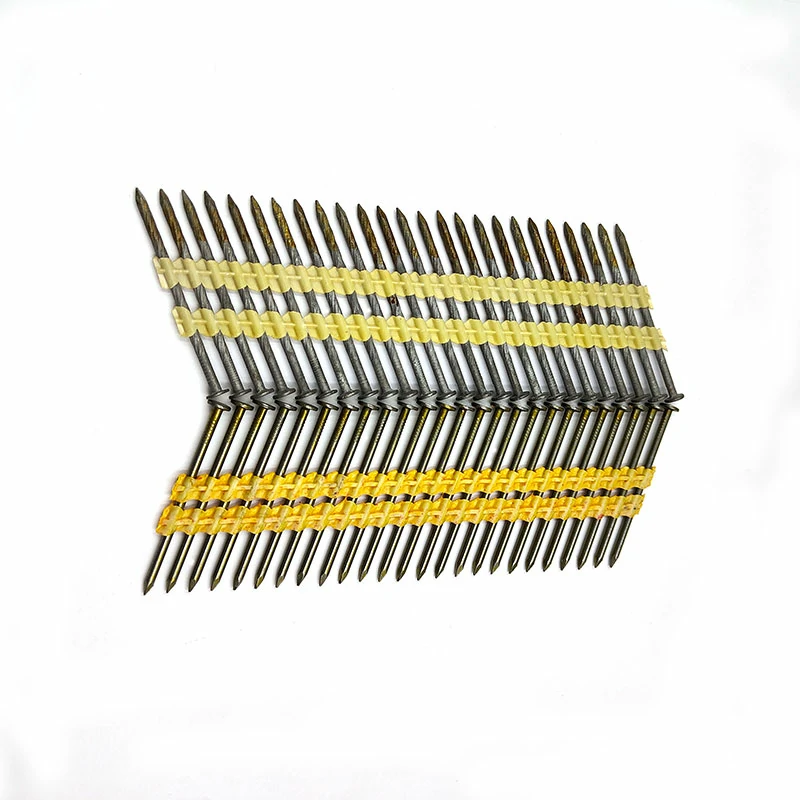

- Nail Material and Coating:

- The material composition of the concrete nails, as well as any coatings or treatments applied to enhance corrosion resistance, can impact shear strength. High-strength materials and effective coatings contribute to the overall durability and performance of the nails.

- Substrate Material:

- The type and characteristics of the substrate material influence shear strength. Concrete and masonry substrates provide higher shear resistance compared to softer materials like wood or plastic. The hardness and density of the substrate are key considerations.

- Embedment Depth:

- The depth to which the concrete nails are embedded into the substrate affects shear strength. Adequate embedment is essential for distributing the load and preventing premature failure. Proper installation, including the use of appropriate tools and techniques, ensures sufficient embedment.

- Pre-Drilling:

- In some cases, pre-drilling pilot holes may be necessary, especially in hard materials like concrete or masonry. Pre-drilling can facilitate easier penetration and enhance the shear strength of the fastened connection by minimizing the risk of splitting or cracking in the substrate.

- Spacing and Layout of Nails:

- The spacing and layout of the nails in the framing structure influence shear strength. Properly distributed and spaced nails contribute to an even load distribution and better overall stability.

- Load Type and Direction:

- The type and direction of applied loads, such as vertical or horizontal forces, affect shear strength differently. Structures subject to lateral forces may require additional considerations for shear resistance.

- Installation Technique:

- The accuracy and precision of the installation process, including the alignment and driving of the nails, impact shear strength. Incorrect installation may lead to reduced shear resistance and compromise the overall integrity of the fastened structure.

- Environmental Conditions:

- Environmental factors, such as exposure to moisture, temperature fluctuations, and chemical agents, can affect the long-term performance and shear strength of concrete nails. Corrosion resistance is particularly important in maintaining shear strength over time.

- Quality of Substrate:

- The quality and condition of the substrate material, including any pre-existing cracks or defects, can influence shear strength. In some cases, substrate preparation or repair may be necessary to ensure optimal fastening.

- Manufacturer Specifications:

- Adhering to the manufacturer’s specifications, guidelines, and recommended practices for the specific type of concrete nails being used is critical. Manufacturers provide valuable information on optimal installation methods and conditions.

It’s important to consider these factors collectively during the design and construction phases to ensure that structures fastened with concrete nails exhibit the desired shear strength and meet safety standards. Consulting with structural engineers, following industry guidelines, and using appropriate materials and installation practices contribute to achieving reliable and durable shear connections.